North America Thermoformed Plastics Market Overview with Detailed Discussion of Key Vendors 2028

North America Thermoformed Plastics Industry Overview

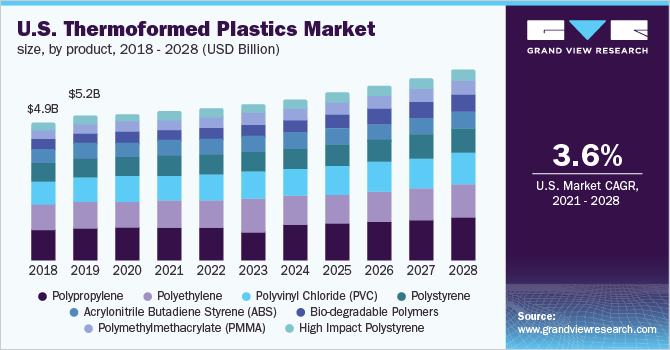

The North America thermoformed plastics market size is expected to reach USD 8.86 billion by 2028, according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 3.8% from 2021 to 2028. Increasing adoption of the thermoformed plastic resin in the consumer goods, food packaging, medical and healthcare, electronics, and automotive sectors is projected to fuel the market growth during the forecast period. Thermoformed plastics reduce the overall weight of the vehicles, which helps in increasing energy efficiency.

North America Thermoformed Plastics Market Segmentation

Grand View Research has segmented the North America thermoformed plastics market based on product, process, application, and country:

Based on the Product Insights, the market is segmented into Polymethylmethacrylate (PMMA), Bio-degradable Polymers, Polyethylene (PE), Acrylonitrile Butadiene Styrene (ABS), Polyvinyl Chloride (PVC), High Impact Polystyrene, Polystyrene (PS), Polypropylene (PP).

- The polypropylene segment accounted for the largest revenue share of more than 20.0% share in 2020. Properties such as good chemical resistance, toughness, integral hinge resistance, translucence, and good heat and fatigue resistance make recycled PP resins suitable for use in automotive foams and bumpers in automobiles, insulator in electrical and electronic devices, and specimen bottles, pill containers, and medical vials.

- Acrylonitrile butadiene styrene(ABS) is gaining prominence in electrical and electronic consumer goods applications owing to the material’s high strength, rigidity, and dimensional stability. Its impact, chemical, and heat resistant ability make it suitable to be used in the manufacturing of enclosures for smartphones and laptops. ABS can be easily blow molded and recycled.

- Polymethylmethacrylate (PMMA) offers high light transmittance and high resistance to UV light, which makes it ideal for outdoor applications exposed to sunlight including skylights, airplane windshields, outdoor signs, and automobile taillights. Volatility in the prices of key raw materials and the growing environmental concerns regarding the disposal of plastic waste has created new opportunities for bio-based polymers.

Based on the Process Insights, the market is segmented into Plug Assist Forming, Thick Gauge Thermoforming, Thin Gauge Thermoforming, Vacuum Snapback.

- The thin gauge thermoforming process segment accounted for the largest revenue share of more than 30.0% in 2020 as thin gauge plastics are usually under .06 inches thick and flexible. The thin gauge thermoforming process is used in disposable and recyclable plastics manufacturing. This makes it suitable to be used in the production of clamshell packaging, candy trays, and protective plastics of cosmetics packaging.

- The thick gauge thermoforming process is used in the production of sturdier and longer-lasting components. In thick-gauge thermoforming, the thickness of thermoplastics enhances the overall durability of each product manufactured and is used for processing acrylonitrile butadiene styrene, polycarbonate, and high-density polyethylene. The thick gauge thermoforming process finds its application in the production of enclosures for medical equipment such as CAT, X-ray, and MRI scan machines, home appliances, and airport luggage totes.

- Plug-assist thermoforming is used to process polyethylene, high-impact polystyrene, acrylonitrile butadiene styrene (ABS), acrylic, and high-density polyethylene (HDPE). This process is widely used in the manufacturing of thermoformed plastics in food packaging, display and outdoor signage, and promotional and branded products such as key rings, trophies, and cups.

Based on the Application Insights, the market is segmented into Medical & Healthcare, Food Packaging, Electrical & Electronics, Automotive, Construction, Consumer Goods & Appliances, Others.

- The food packaging application segment led the market and accounted for a revenue share of more than 40.0% in 2020. Improved shelf life, coupled with heightened efficiency in the prevention of content contamination, is expected to boost the growth of the market. In addition, factors such as increasing population, rising disposable income, and shrinking households are having a positive impact on the market growth.

- The presence of major automotive manufacturers has augmented the demand for thermoformed plastics for the manufacturing of products, such as seating parts, dashboards, bumpers, air ducts, truck bed liners, floor mats, and headlights. Moreover, the favorable government initiatives, subsidies, and tax rebate programs to promote electric vehicle adoption are expected to fuel the market growth in North America.

North America Thermoformed Plastics Country Outlook

- U.S.

- Canada

- Mexico

Key Companies Profile & Market Share Insights

The North American market is characterized by the presence of key players, along with a few medium and small regional players. Established players such as Placon are investing in the development of innovative and sustainable solutions for the development of their product portfolio, thus giving them an edge over their competitors.

Some of the prominent players operating in the North America thermoformed plastics market include,

- Pactiv LLC

- Sonoco Products Company

- CM Packaging

- Placon

- Genpak, LLC

- Anchor Packaging LLC

Order a free sample PDF of the North America Thermoformed Plastics Market Intelligence Study, published by Grand View Research.